Since Robin started placing implants over 20 years ago, there’s been huge technological advances to make this surgery minimally invasive, safer, faster and incredibly accurate with better positioning. This has been achieved with scans and planning software and of course the X-Guide for fully navigated pre-planned surgery. However, it has always been difficult and time consuming in ‘teeth in a day’ cases to make temporary teeth that fit accurately over the newly placed implants and not disturb them-implants can fail if the temporary teeth are not perfectly fitting. And it has been extremely difficult to do this minimally invasively. UNTIL NOW!

We now have the last piece of the jigsaw puzzle with photogrammetry and 3D printing and this is COMING SOON to Wayside.

Photogrammetry is the science of making accurate surveys using photographs (thousands of them) taken from many angles by more than one camera and in layers to create accurate records and measurements. Traditionally it has been used for mapping and surveying. But with the advent of 3D printing, it is now used to ‘map’ physical objects we want to print. In implant dentistry we are mapping the implant positions, and it is the most precise and accurate method of recording the position of multiple implants.

It is a game changer in dentistry as conventional impression methods have many inherent factors which affect accuracy. Also, these traditional impressions can be very uncomfortable.

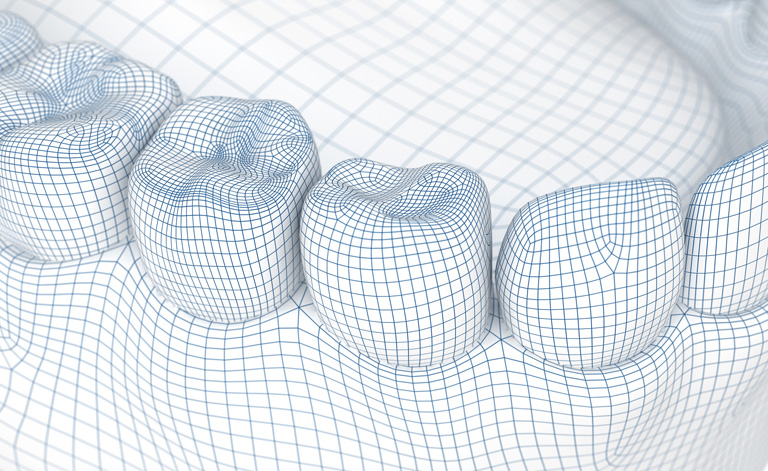

3D printing is the process of making a physical object from a three-dimensional digital model. It lays down many thin layers of material in succession to create the object. The largest thing to be 3D printed was a 25m boat! Dental 3D printers are of course much smaller!

The data we can get from scans and photogrammetry allows us to make digital 3-dimensional models that we can use, with the help of clever software, to plan mouthguards, whitening trays, crowns, bridges and dentures. This plan is saved in a format that the 3D printer can read and use to print.

We will have the software for photogrammetry in July and can’t wait to get started.